- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

A Comprehensive Guide to Plate Disposable Filter

The Plate Disposable Filter, a versatile and practical filtration device, has gained widespread popularity in various industries. In this comprehensive guide, we will explore the applications, advantages, and significance of the Plate Disposable Filter, shedding light on its importance in modern filtration processes.

Introduction to Plate Disposable Filter

The Plate Disposable Filter is a specialized type of filtration system designed to remove solid particles and impurities from liquids. It consists of multiple filtering plates, made from materials such as polypropylene or stainless steel, stacked together in a compact arrangement. These filters are used for both small-scale laboratory applications and large-scale industrial processes.

How Plate Disposable Filters Work

Filtration Process

The filtration process begins with the liquid to be filtered being introduced into the filter chamber. As the liquid passes through the filtering plates, the solid particles and impurities are trapped on the surface of the plates, while the clarified liquid flows through. The filtration continues until the filter plates are filled with accumulated solids.

Disposable Nature

As the name suggests, Plate Disposable Filters are designed for single-use applications. Once the filtering plates are filled, the entire unit is discarded, eliminating the need for cleaning and reducing downtime between filtration processes.

Further reading:Barbed Wire: Securing Boundaries with Uncompromising Protection

Magnesia Carbon Brick: A High-Performance Refractory Solution

How Does a 358 Security Fence Differ from Other Types of Fences?

Prestressing Strand: Revolutionizing Structural Engineering

How to Prevent 3 Common Metal Filter Problems

How to Choose the Right Tungsten for TIG Welding?

How do Graphite Blocks Compare to Other Refractory Materials?

Advantages of Plate Disposable Filters

Convenience and Time-Saving

Plate Disposable Filters offer exceptional convenience in filtration processes. With their disposable nature, there is no need for cleaning or maintenance, leading to significant time-saving benefits.

Cost-Effective

Plate Disposable Filters can prove to be cost-effective, especially in applications where frequent Air Filter changes are required. The elimination of cleaning and maintenance costs contributes to overall savings.

Reduced Contamination Risk

Since Plate Disposable Filters are discarded after use, there is a reduced risk of cross-contamination between different filtration processes, ensuring consistent and reliable results.

Versatility

Plate Disposable Filters are available in various sizes and materials, making them versatile and adaptable to different liquid filtration requirements.

How Much Do You Know Steel Rail Weight and Length?

The Benefits of Using Stainless Steel Wire Mesh

Hexagon Metal Mesh: A Versatile and Stylish Choice for Various Applications

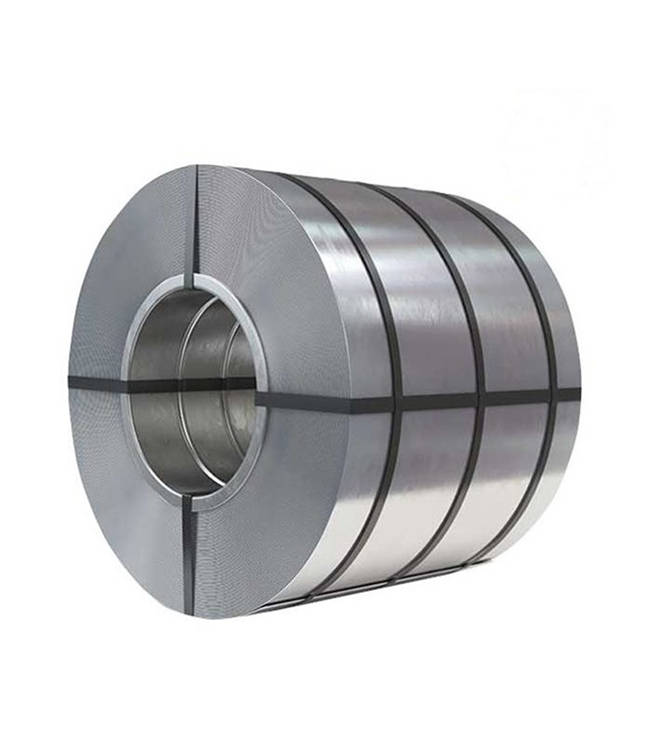

Which industries commonly use color-coated steel coils?

High Bulk Density Graphite Block: The Ultimate Guide

Applications of Galvanized Steel Coil

Exploring the Versatility and Benefits of Hinge Joint Fences

Previous

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0