- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

What is the best blade for cutting concrete?

Selecting the right blade for cutting concrete is crucial to achieving clean cuts, minimizing dust, and ensuring safety. Let's explore the factors to consider when choosing the best blade for cutting concrete:

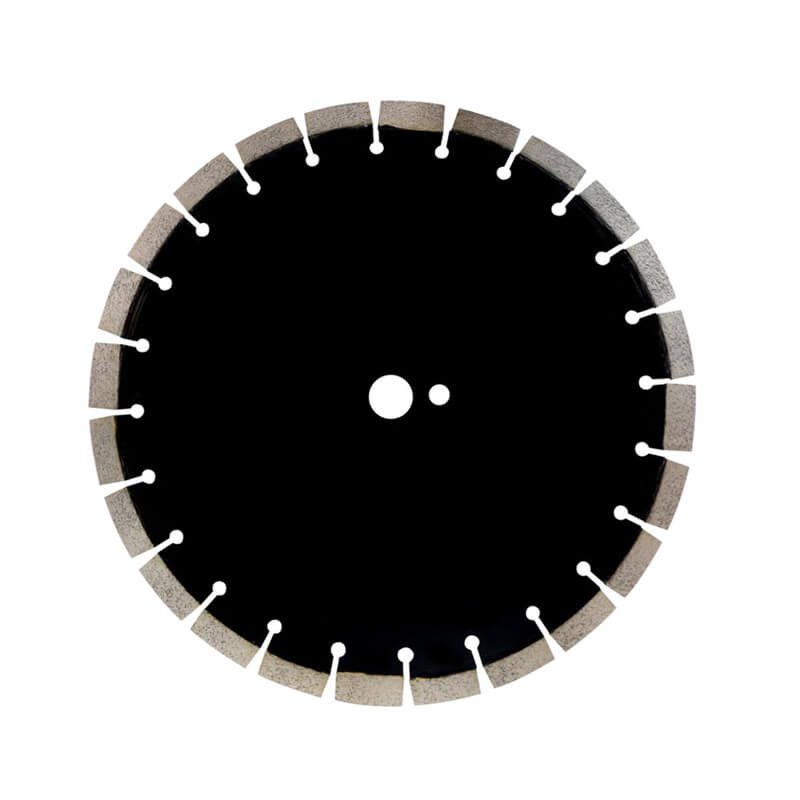

Diamond Blades

Diamond blades are widely regarded as the best option for cutting concrete. These blades feature diamond segments bonded to the cutting edge, allowing them to grind through concrete with ease. Diamond is one of the hardest materials known, making it ideal for cutting through tough concrete surfaces.

Segmented vs. Continuous Rim Blades

When it comes to diamond blades for cutting concrete, there are two main types: segmented and continuous rim blades. Segmented blades have gaps between the diamond segments, which help dissipate heat and reduce the risk of blade binding. Continuous rim blades, on the other hand, have a smooth, continuous edge that provides a cleaner cut but may be prone to overheating.

Blade Size and Arbor Size

The size of the blade and the arbor size must match the specifications of the concrete cutting tool being used. Common blade diameters for cutting concrete range from 4 inches to 14 inches or more, depending on the depth of cut required. Additionally, ensure that the arbor size of the blade matches the arbor size of the cutting tool to prevent compatibility issues.

Wet vs. Dry Cutting

Further reading:The Ultimate Guide to Choosing Electroplated Diamond Cup Grinding Wheel

The Advantages Of Using Diamond-Tipped Saw Blades

Which hand saw is best for beginners?

4 Tips to Select Garden Hose Connectors

Best cordless garden tools: in-depth buyer's guide

Unleashing the Cutting Power: Choosing the Perfect Saw Blade for Your Woodworking Needs

How do I know if my saw blade is good?

Diamond blades for cutting concrete are available in both wet and dry cutting configurations. Wet cutting involves using water to cool the blade and suppress dust during cutting, resulting in cleaner cuts and longer blade life. Dry cutting, on the other hand, does not use water and may produce more dust, but it offers greater convenience in certain situations where water is not readily available.

Blade Quality and Price

Investing in a high-quality diamond blade may initially cost more, but it can save money in the long run by lasting longer and providing better performance. Cheaper blades may wear out quickly, leading to frequent blade replacements and potentially compromising the quality of the cuts. Consider the blade's quality and price relative to its intended use and the frequency of cutting concrete.

Safety Considerations

When using diamond blades for cutting concrete, safety should always be a top priority. Wear appropriate personal protective equipment, including safety glasses, gloves, and a dust mask, to protect against debris and airborne particles. Follow proper cutting techniques and adhere to manufacturer recommendations for safe operation of the cutting tool and blade.

Conclusion

In conclusion, diamond blades are the best option for cutting concrete due to their durability and effectiveness. When choosing a diamond blade, consider factors such as blade type (segmented or continuous rim), size, arbor size, cutting method (wet or dry), quality, and price. By selecting the right blade for the job and following safety precautions, you can achieve clean, precise cuts in concrete while minimizing dust and ensuring safety.

What is better carbide or diamond blade?

Beryllium Copper Non-Sparking Hand Tools: An In-Depth Guide for Workplace Safety

Quick Change Tooling: Advantages and Considerations for CNC Magazine Systems

Case Studies in Oilfield Casing Success: Real-World Applications and Benefits

The Essential Guide to Mining Tools: Types, Uses, and Maintenance

What Is The Difference Between A Claw Hammer And A Split Hammer?

How diamond saw blades improve the smoothness of stone cutting

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0