- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Understanding the Cost Factors of Steel Trusses

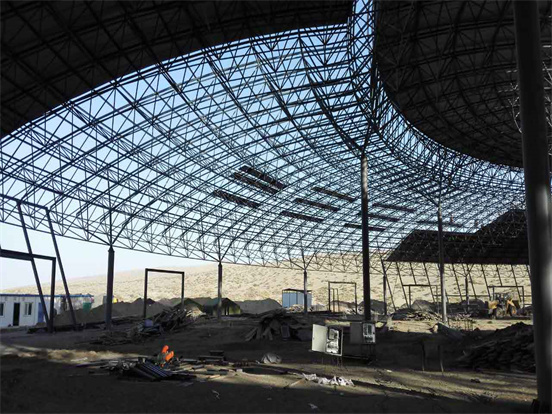

Steel trusses are widely used in construction projects, offering structural stability, strength, and versatility. If you're considering incorporating steel trusses into your building project, it's essential to understand the factors that influence their cost. In this article, we will explore the various elements that determine the cost of steel trusses and provide you with insights to make informed decisions.

1. Truss Design and Complexity

The design and complexity of the steel truss play a significant role in determining its cost. The more intricate the truss design, involving complex geometries or specialized connections, the higher the fabrication costs are likely to be. Customized designs may require additional engineering expertise, resulting in increased costs compared to standard truss designs.

2. Span Length and Size

The span length and size of the steel truss directly impact its cost. Longer spans and larger truss sizes generally require more materials, increased fabrication time, and specialized equipment for handling and installation. These factors contribute to higher costs compared to shorter spans and smaller trusses.

3. Steel Material and Grade

The type and grade of steel used in the truss construction influence the cost. Different steel grades offer varying strength and durability characteristics, and their prices can vary accordingly. High-strength steel grades, such as ASTM A992 or A572, are often used for structural applications, but they may come at a higher cost than lower-grade steels.

4. Fabrication and Manufacturing

Related articles:Construction & Real Estate

Why Do People Like Shipping Container Homes?

What is the difference between strip seal and modular expansion joint?

The Mesmerizing World of Music Fountains

What are the different types of redispersible polymer powder?

Are FRP Backwater Tanks the Future of Sustainable Water Management?

Choosing the Right Geogrid for Your Project: Factors to Consider

The fabrication and manufacturing processes involved in producing steel trusses also contribute to their overall cost. Factors such as welding complexity, surface finishes, additional treatments (e.g., galvanizing or painting), and the labor required for assembly and quality control affect the final price. Additionally, if the trusses need to be transported long distances, shipping costs may be a consideration.

5. Site-specific Considerations

Site-specific factors can impact the cost of steel trusses. These factors include the location of the construction site, accessibility, local building codes and regulations, labor costs, and market conditions. It's important to account for these variables when estimating the overall cost of incorporating steel trusses into your project.

6. Quantity and Supplier

The quantity of steel trusses needed and the choice of supplier also influence the cost. Ordering a larger quantity of trusses may result in volume discounts from suppliers. Additionally, selecting a reputable supplier with a track record of delivering quality products can impact the cost due to variations in pricing and service levels across different steel trusses suppliers.

Conclusion

The cost of steel trusses is influenced by several factors, including the truss design and complexity, span length and size, steel material and grade, fabrication and manufacturing processes, site-specific considerations, quantity, and supplier choice. It's crucial to work closely with experienced professionals, such as structural engineers and steel fabricators, to evaluate these factors and obtain accurate cost estimates for your specific project requirements.

What is Construction Grade HPMC?

What are the benefits of film faced plywood?

Expandable Container Houses: An Innovative Solution for Modern Living

From Snowmobiles to Snow Groomers: The Evolution of Snow Maintenance

Redispersible Polymer Powder: The Secret Ingredient in Durable Construction Materials

Why B2B Customers Should Prioritize the Reliability of Hydraulic Elevator Dams

Reducing Maintenance Costs: The Economic Benefits of Rubber Dams

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0