- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Synchronous vs. Asynchronous Motors: Which Is Best for Your Application?

When it comes to choosing the right electric motor for your industrial or commercial application, one of the fundamental decisions is whether to opt for a synchronous motor or an asynchronous motor. Both motor types have their advantages and are suitable for various applications.

Understanding Synchronous Motors

Synchronization: Synchronous motors operate at a fixed speed that is synchronized with the frequency of the power supply. In many cases, this speed is 1,800 or 3,600 revolutions per minute (RPM) for motors in North America and 1,500 or 3,000 RPM for motors in other regions.

Applications: Synchronous motors are often used in applications where precise speed control is essential, such as in clocks, timers, and some industrial machinery. They are also commonly found in power factor correction systems.

Advantages: Synchronous motors offer excellent efficiency at their rated speed, making them ideal for applications that require constant speed, high precision, and power factor correction.

Challenges: Synchronous motors can be less efficient and less effective at lower speeds or when subjected to variable loads. They also require external devices, such as a synchronous motor controller or a variable frequency drive (VFD), for speed control.

Understanding Asynchronous Motors (Induction Motors)

Asynchronous Operation: Asynchronous motors, also known as induction motors, operate at a speed slightly lower than the synchronous speed. This speed difference, called slip, allows them to handle variable loads and adjust their speed as needed.

Applications: Asynchronous motors are widely used in various applications, including pumps, fans, compressors, conveyors, and most industrial machinery. Their versatility and ability to handle varying loads make them popular in many industries.

Advantages: Asynchronous motors are simple, reliable, and cost-effective. They are known for their ability to handle high torque loads during startup and under variable conditions.

Challenges: While asynchronous motors are versatile, their speed control is not as precise as synchronous motors. They may experience reduced efficiency at partial loads compared to synchronous motors.

Advancing Surface Finishing: The Skiving Roller Burnishing Machine

Top 5 Reasons to Invest in Latex Gloves Manufacturing

Benefits of Using DOD Large Character Inkjet Printer for Product Labeling and Packaging

Which welding machine is best for home use?

A Comparative Analysis of Vertical Rolling Machines and Horizontal Rolling Machines

Extrusion Blow Molding Machine: Overview and Function

What is the process of valve grinding?

Choosing the Right Motor for Your Application

Now that we've highlighted the differences, consider the following factors when choosing between synchronous and asynchronous motors:

Speed Control: If your application requires precise speed control and operates at a constant speed, a synchronous motor may be the better choice.

Variable Loads: For applications with variable loads or where speed fluctuations are acceptable, asynchronous motors are often more suitable.

Cost: Asynchronous motors are generally more cost-effective and require fewer additional components for operation.

Power Factor Correction: If power factor correction is a critical consideration, synchronous motors excel in this regard.

Torque Requirements: Consider the torque requirements of your application, as synchronous motors may not handle high torque loads during startup as well as asynchronous motors.

The choice between synchronous and asynchronous motors depends on the specific requirements of your application. While synchronous motors offer precise speed control and excel in power factor correction, asynchronous motors are versatile, cost-effective, and well-suited for variable load scenarios. Carefully evaluating your application's needs will help you make the right choice and ensure optimal performance and efficiency.

Related:

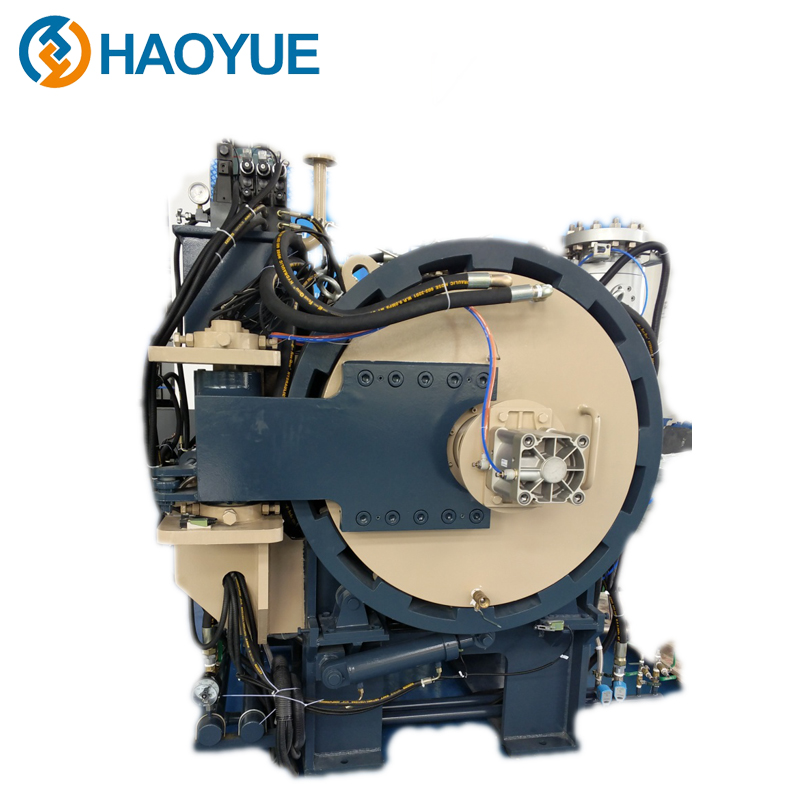

187.5RPM 400KW Synchronous Motor

40p 1600KW High Voltage Permanent Magnet Synchronous Motor

Further reading:Valve Lapping Machine: Precision and Efficiency in Valve Seating

Exploring the Sustainability of Recycled Concrete

A Comprehensive Comparison between Rotary Drilling Rigs and Percussion Drills

How Does a Wire Straightener Work?

Advancing Precision and Power: The Dual Action Hydraulic Cylinder

EPS Shape Moulding Machine for Lost Foam Casting: Revolutionizing Casting Processes

How does a Puff Snacks Extruding Machine work?

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0