- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery

- Measurement & Analysis Instruments

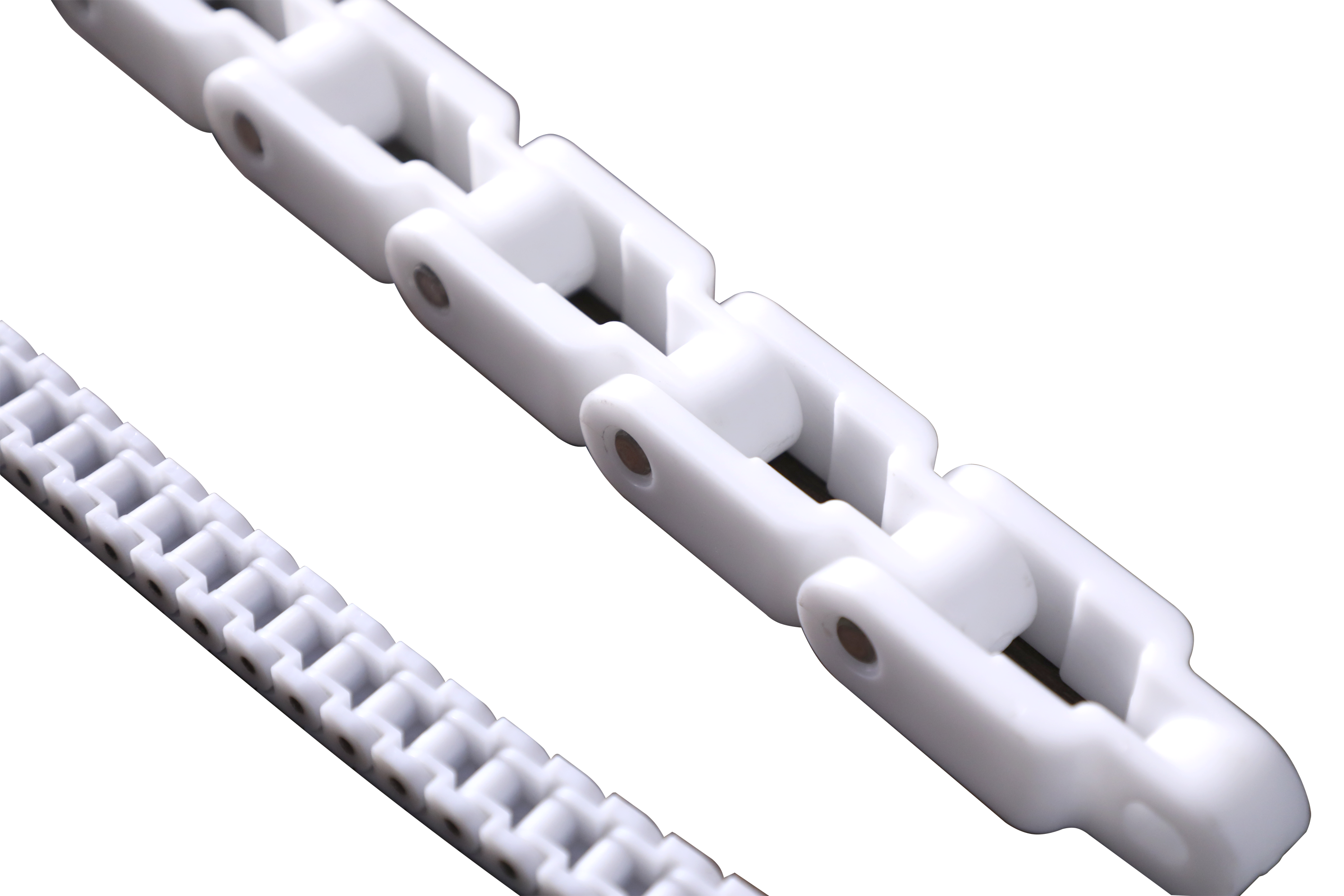

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Maximizing Performance: The Importance of Ground Engaging Parts

Goto G-Top to know more.

**Maximizing Performance: The Importance of Ground Engaging Parts**.

**Step 1: Understand the Role of Ground Engaging Parts**.

Ground engaging parts are crucial components of heavy machinery, such as excavators and bulldozers. These parts come into direct contact with the ground and are responsible for tasks such as digging, scraping, and pushing. Understanding the role of ground engaging parts is essential for maximizing performance and efficiency.

**Step 2: Regular Inspection and Maintenance**.

To ensure optimal performance, it is important to conduct regular inspections of ground engaging parts. Check for signs of wear and tear, such as cracks or deformation. Replace any damaged parts promptly to prevent further damage to the machinery.

**Step 3: Choose the Right Ground Engaging Parts**.

Selecting the right ground engaging parts for your specific application is crucial. Consider factors such as the type of terrain, the material being worked with, and the intensity of use. Choosing the right parts can greatly enhance performance and longevity.

**Step 4: Monitor Wear Patterns**.

Monitoring the wear patterns of ground engaging parts can provide valuable insights into the machine's performance. Uneven wear can indicate issues with the machinery or improper use of the parts. Addressing these issues promptly can help prevent costly repairs and downtime.

Further reading:Which Sany G model is best for off-roading?

What are the best cat bucket teeth adapters?

How Does affordable car maintenance services Work?

Drilling casing: the ultimate guide

10 Questions You Should Know about 2713-1221tl

The Benefits of Using uniteeth

4 Tips to Choose Volvo Bucket Teeth

**Step 5: Proper Operation and Training**.

Proper operation of heavy machinery is key to maximizing performance and ensuring the longevity of ground engaging parts. Provide adequate training to operators to ensure they understand how to use the machinery effectively and safely. This can help prevent unnecessary wear and damage to the parts.

**Step 6: Implement a Maintenance Schedule**.

Developing a regular maintenance schedule for ground engaging parts is essential for maximizing performance. Regularly clean and lubricate the parts to prevent rust and corrosion. Conduct routine inspections and replace parts as needed to prevent unexpected breakdowns.

**Step 7: Work with Trusted Suppliers**.

When purchasing ground engaging parts, it is important to work with trusted suppliers who offer high-quality products. Choosing genuine parts from reputable suppliers can help ensure the reliability and performance of the machinery.

By following these steps and emphasizing the importance of ground engaging parts, you can maximize the performance of heavy machinery and extend the lifespan of essential components. Prioritizing proper maintenance, operation, and part selection can lead to improved efficiency and cost savings in the long run.

Please visit our website for more information on this topic.

For more loader cutting edge manufacturerinformation, please contact us. We will provide professional answers.

Further reading:What are the benefits of Custom Size RC543 DTH Drilling Bits?

Key Questions to Ask When Selecting Electric Bike Accessories for Your Next Adventure

Essential Guide to Exporting External Hex Flange Screws to Barbados

Key Questions to Consider When Purchasing Internal Hex Screw Pricing in Sint Maarten

Discovering Internal Hex Screw Prices in Barbados

How to Find Internal Hex Screw Price in Colombia?

10 Factors You Should Consider About Internal Hex Screw Price in Peru

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0