- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

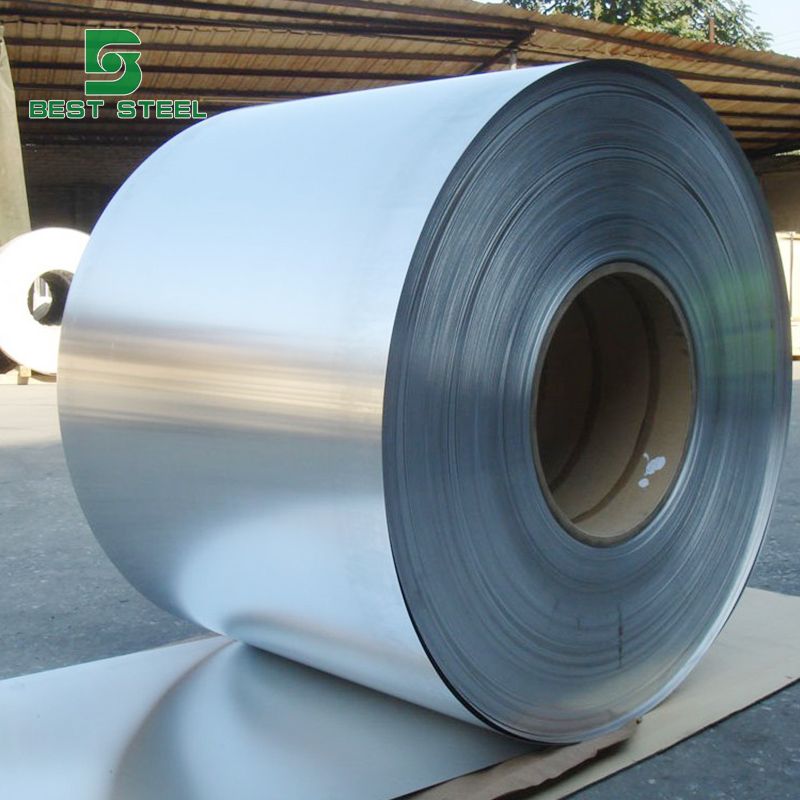

Installation Guide for Galvanized Corrugated Steel Plate: Tips and Techniques

Installing galvanized corrugated steel plate requires proper planning, preparation, and execution to ensure a successful and durable installation. Here is a comprehensive installation guide that provides tips and techniques for installing galvanized corrugated steel plates effectively:

Safety Precautions:

Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and steel-toed boots.

Use caution when handling sharp edges and tools.

Work with a team when handling large and heavy plates to prevent injuries.

Planning and Preparation:

Measure the installation area accurately and determine the quantity of steel plates required.

Ensure that the supporting structure is in good condition and capable of handling the load.

Check local building codes and regulations for specific requirements and guidelines.

Tools and Equipment:

Gather the necessary tools and equipment, including a measuring tape, chalk line, drill with appropriate bits, screwdriver, roofing nails or screws, and a saw for cutting the plates if needed.

Surface Preparation:

Clean the installation surface to remove any dirt, debris, or loose material.

Repair or replace damaged sections of the supporting structure as necessary.

Ensure the surface is level and free from any irregularities that may affect the installation.

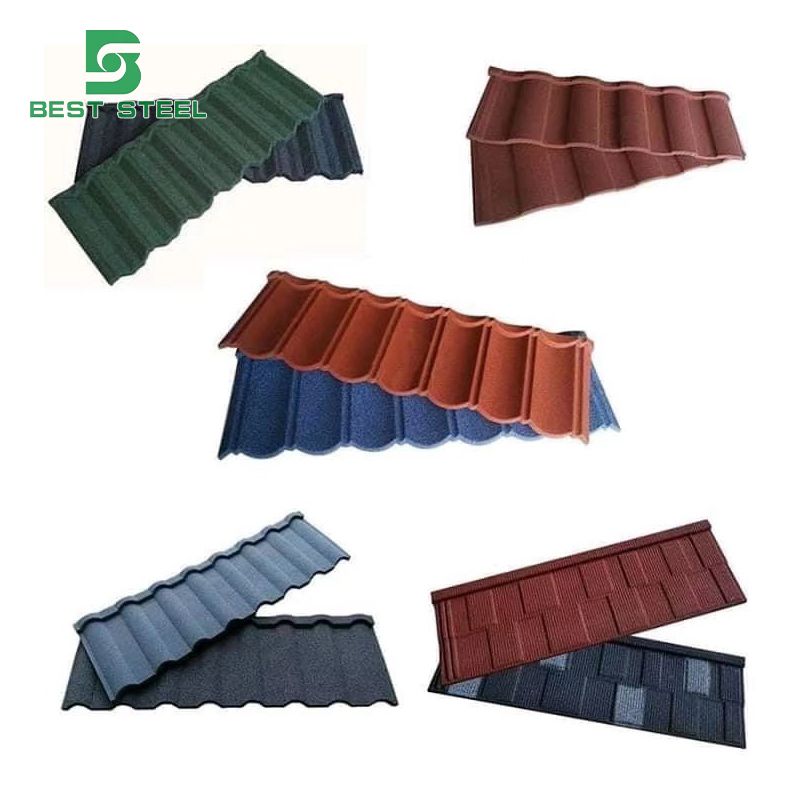

Roofing Installation:

Start the installation at the bottom edge of the roof, aligning the first plate with the edge of the roof and overlapping any eaves or gutters.

Secure the first plate by drilling holes through the pre-marked locations and attaching it to the supporting structure using roofing nails or screws. Use neoprene washers for added weatherproofing.

Related articles:Construction & Real Estate

The Ultimate Guide to PE Coated Tarpaulin

Mastering the Art of Drywall Paper Tape

Creative DIY Uses for Flexible Metal Corner Tape: Which project will you try first?

LVL Scaffolding Plank: The Ultimate Solution for Sturdy and Efficient Construction Work

Features and Advantages of Welded Gabion Wire Mesh

What is the difference between rubber and foam rubber?

Continue installing subsequent plates, ensuring proper overlap and alignment. Use a chalk line to maintain straight lines.

Cut the plates to size as needed using a saw with a blade suitable for cutting metal.

Overlap adjacent plates by at least one corrugation to ensure a watertight seal.

Wall Cladding Installation:

Install the first plate at the bottom of the wall, aligning it with the desired starting point.

Secure the plate to the wall using appropriate fasteners, such as screws or nails, ensuring they penetrate the supporting structure for secure attachment.

Install subsequent plates, overlapping them properly to create a seamless appearance.

Use a level or plumb line to ensure the plates are installed vertically and maintain consistent alignment.

Finishing Touches:

Trim any excess material using a saw or tin snips to achieve a clean and finished look.

Seal any gaps or joints with appropriate sealants or flashing materials to prevent water infiltration.

Conduct a thorough inspection of the installation to ensure proper attachment, alignment, and weatherproofing.

Maintenance:

Regularly inspect the galvanized steel plates for any signs of damage, rust, or loose fasteners.

Clean the plates periodically to remove dirt, debris, and potential contaminants.

Address any repairs or maintenance issues promptly to extend the lifespan of the installation.

It's essential to consult the manufacturer's guidelines and specifications for specific recommendations on installation techniques and best practices. Following this installation guide and employing proper techniques will help ensure a successful and long-lasting installation of galvanized corrugated steel plates.

Further reading:Laminated Bridge Bearings: Enhancing Safety and Structural Performance

An Overview of Agricultural Water Storage Tanks

Why You Need a Corrugated Steel Pipe?

Pool Mosaics: Transforming Your Swimming Pool into a Work of Art

The Essential Guide to Welded Pipe Caps: Uses, Installation, and Benefits

Advantages of Choosing Granite Headstones for Lasting Memorialization

Why is the Shipping Container House Trend Gaining Popularity Among Homeowners and Architects?

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0